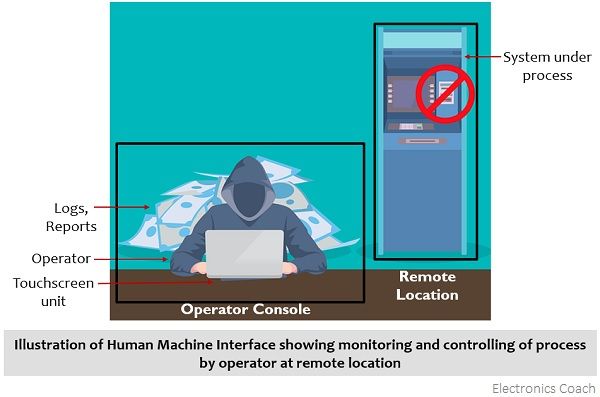

Human-Machine Interface abbreviated as HMI is a user interface which is a combination of hardware and software that permits easy interaction between human and machine. Thus, it is named so. The main purpose of establishing such an interaction between humans and machines is to control and monitor the processes ongoing at the remote locations without physically being present at that particular location.

The human-machine interface is a crucial component of automated industrial processes and thus is of significant importance in SCADA systems.

Basics of HMI

The human-machine interface is a famous name given to a hardware and software combination that offers interaction between human and system (machine). Some other names used to denote HMI are man-machine interface, operator interface terminal, operator terminal, etc. In technical terms, HMI is a screen like a computer screen or touchscreen that allows the user to interact with the device. It mainly finds applications in industrial processes thus is regarded as a crucial component of SCADA systems.

Its major aim is to ensure effective operation through controlling of the system which is being monitored. This is done by a human operator that takes the operational decisions and holds the power for manual overriding of automatic control operation in case of emergency.

Importance of Human-Machine Interface

Earlier, in the absence of HMI, to view any mechanical progress, the operator must be physically present at the remote locations to record the progress as well as to do the needful in case of any kind of change of process or emergency. While HMI was designed with the aim of supervision of industrial processes. It acts as a centralized station that is used for the purpose of displaying the data of ongoing processes along with providing the controlling authority to the operator. Thus, the advent of HMI has made things easier and less time taking.

In small SCADA systems, the control engineer or operator is responsible for configuring the setpoints and control algorithms within the controller. While, in medium or large SCADA systems, it is also responsible for providing process status information along with historical information and reports to operators, administrators, and authorized users.

Functions of HMI

The major functions of the human-machine interface are as follows:

- Visualizing data display.

- Monitoring the inputs and outputs of the machines.

- Tracking of production time, trends, etc.

- Performing the required changes when needed.

We have already mentioned in the beginning that HMI establishes the interaction between a user and the system on which a process is going on at a remote location.

Basically, HMIs have special software which is programmed by engineers. The engineers design the software according to the region where the HMI is required to be used as this will provide the idea regarding the information which is to be displayed on the screen along with the necessary buttons that are required to be pushed keeping in mind the outcome of operation performed.

It works in a way that the information obtained while communicating with PLCs and input/output sensors is displayed on the screen. This displayed information is used for monitoring or tracking or sometimes with the purpose of executing operations like turning off the machine, increasing the operational speed, etc. The centralized information helps in easy accessing of the data which is present in the form of graphs, charts, digital dashboards, etc. to the user. So, basically through HMI, the human operator can directly manage the operations ongoing at the remote locations with proper hardware and software utilities.

The centralized information helps in easy accessing of the data which is present in the form of graphs, charts, digital dashboards, etc. to the user. So, basically through HMI, the human operator can directly manage the operations ongoing at the remote locations with proper hardware and software utilities.

Components of Human-Machine Interface

The building block of HMI involves the following components:

1. Operator Console: The operator console is a very important part of HMI as it has various units like visual display units (VDUs), pointer/cursor, keyboard, and communication facilities, etc. The VSUs are basically monitoring screens like CRT, LED, LCD, etc. with antiglare screen coating. The work of cursor is performed by mouse, trackball, or the touch-screen facility. All the monitors share a keyboard and cursor which moves through all the screens without user intervention.

In SCADA systems, a single operator handles around 3 to 4 monitors so as to have a display facility with full graphics that facilitates proper planning and monitoring of the system. Audible alarms are also present at the operator console that intimates the operator regarding the event occurring in the system and also informs the user whenever there is a need to change the existing event.

Thus, the infrastructure (inclusive of table and chair) of the operator console must be suitable enough so that the operator comfortably monitors the operation during the duty period.

2. Operator Dialogue: Dialogue boxes act as a communication bridge between the operator and the computer. It pops up whenever there is any information to be given or in case of any query while operating. The engineer must design it in the easiest possible way so that its commands are simple and easily understandable. The function keys present in the keyboard are programmed so that any major changes do not require much of the operator’s efforts.

3. Mimic Diagram: In the large station center, a mimic diagram is a crucial component through which the operator gets the full view of the processes under control. This needs large multiple screen displays like LCDs or LEDs with SCADA operability. There is a mosaic map board either of static or dynamic nature which is directly linked to HMI. So, this offers upgradations of the map board directly at the time when HMIs are upgraded.

4. Peripheral devices: The peripheral devices used in interconnection with HMIs are printers. Majorly these are of 3 types, one is used to print the alarms and SOEs. A color printer is used to capture screenshots. While the third one is a laser printer which is black and white that prints the latest reports.

Software Functionalities of HMI

The software of the human-machine interface is highly dependent on the region of operation of the system and the performance requirement along with its integration and cost. So, the various software functionalities are as follows:

- To protect the system from unauthorized access, the console must be incorporated with role-based access security controlling. HMI acts as a crucial end node of the SCADA system thus, must be accessed only by using the proper id and password.

- The designed HMI software must be such that it must properly display the information regarding the power system and associated parameters like voltage, current, frequency, etc. so as to provide an exact idea about the ongoing process. It must be designed in a user-friendly manner that only simple efforts can make the user understand the process in progress to take necessary actions whenever required.

- The software must generate reports and logs timely and must provide necessary calculative values for the purpose of future references. This is so because various interconnected units require the process reports many times for different purposes.

Uses of HMI

As HMIs are majorly used for the purpose of handling various industrial processes thus, these are used by various industrial organizations and companies worldwide including:

- Oil and Gas,

- Power and Energy,

- Manufacturing and Recycling,

- Water and waste-water management,

- Transportation, etc.

Examples of Human-Machine Interface

Basically, screens with keyboards, touchscreens act as HMI that allows monitoring and controlling of various remote processes. On a general basis, the most common example of HMI is the ATM machine. Through an ATM, one can easily withdraw or deposit money from their respective accounts using the pushbuttons and touch-screen facilities.

Leave a Reply