Definition: The word Thermistor is formed by two words Thermal and Resistor. It is a solid state device in which resistance varies with the ambient temperature. Most thermistors possess negative temperature coefficient. Only few exhibit positive temperature coefficient.

You must be thinking what is negative temperature coefficient and what is positive temperature coefficient? May be some of the readers are aware of this term, but the beginners may not have heard this term before. So let us discuss first these two terms.

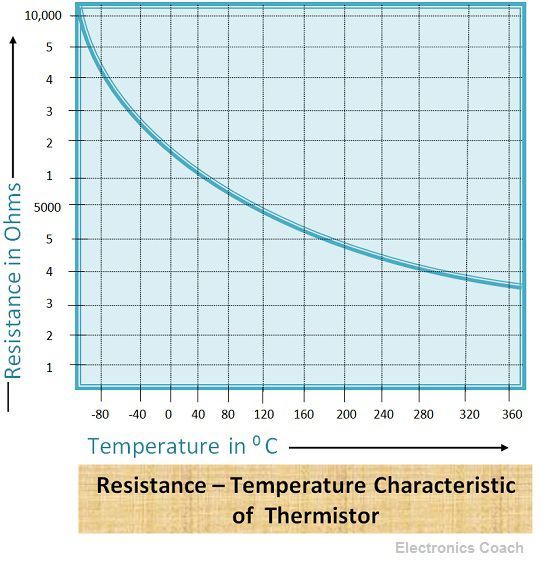

If the device possesses negative temperature coefficient, it means the resistance of the device decreases with the increase in temperature. But if the device possesses positive temperature coefficient, then the resistance of the device increases with the increase in temperature.

Thus, the thermistor is a semiconductor device which possesses high negative temperature coefficient (about -0.04 per 0C at room temperature of 250C).

Manufacturing Process of Thermistor

The thermistors are manufactured from the oxides of metals such as cobalt, copper, iron, zinc, nickel, manganese, titanium, magnesium and uranium. The sulphides of these metals or silicates are also used for manufacturing thermistors. The semiconductors such as germanium and silicon are not used for manufacturing thermistor because they possess low-temperature coefficient.

On the other hand, the metal oxides possess a large and predictable value of temperature coefficient which is considered appropriate for the manufacturing process of a thermistor. The process of manufacturing starts from milling these metal oxides or sulphides of metals into powdered form.

After this process, these oxides are mixed in proper proportion with the binders and then pressed into the desired shape. Then, finally, the process of sintering is done. The electrical terminals can be embedded either before sintering or after sintering. If it is done after sintering it can be baked afterwards.

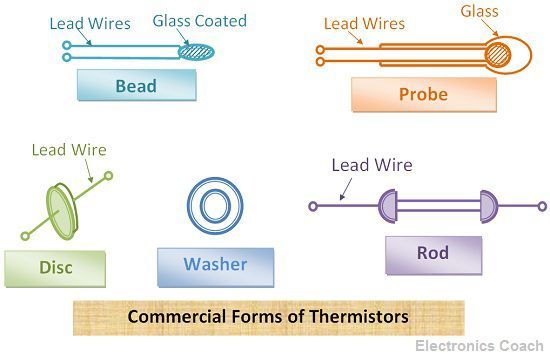

The range of thermistors at room temperature (250C) varies from several 100 Ω to megaohms. They can be manufactured in very small shapes in the form of beads, rods and discs.

Working of Thermistor

We have already discussed above that thermistor works on the principle of negative temperature coefficient. Although the decrease of resistance with the increase in temperature is undesirable in many electrical and electronic circuitry, it is significant for temperature detection circuits.

The thermistor is two terminal nonlinear devices in which the resistance starts falling rapidly when the temperature of the surrounding increases. This happens because when the temperature rises, the concentration of charge carriers also starts increasing due to which the resistance of the path starts falling. Thus, at a higher temperature, the current flowing through the resistor is more as compared to lower temperature.

When the thermistor is heated to 1500C the resistance of the thermistors decreases by 500 times. When the current through the thermistors starts rising it also gives rises to power dissipation. As a consequence of power dissipation again the temperature of the device starts rising. Thus, at fixed ambient temperature the resistance of the thermistors depends upon power dissipation through the device.

Resistance of Thermistor

The resistance (R) of the thermistor is related to temperature (T) by the following relationship below

R = R0 α e β/T

Where α and β are the constants, depending upon the material used and manufacturing techniques.

The above equation can be re-written to derive the relationship between resistance and temperature.

R1 = R0 e [β(1/T1)-(1/T0)]

Where R1 and R0 are the value of resistance at temperatures T1 and T0 respectively and β is the thermistor constant, it is expressed in kelvins and it is of order 4000. The temperature T0 is usually taken as room temperature i.e. 250C or 298 K. The value of β changes with the increase of temperature, but if it assumed to be constant the relationship between temperature coefficient and resistance and temperature can be obtained.

α= dR1/R1 dT = -β/T2

where α is the temperature coefficient.

A thermistor is a solid state device which is manufactured by metal oxides, thus they possess negative temperature coefficient when the electrons in the outermost shell of metal are in the active state. While when the electrons of the molecule of the manufacturing material is inactive the thermistors possesses positive temperature coefficient.

The thermistors are available in different types on the basis of operating temperature and response time. The conventional thermistors are likely to get affected by moisture and outer atmospheric conditions. If we want to use in some application where we require the device to get protected from outer conditions then hermetically sealed thermistors should be used. They are sealed so that the moisture does not interrupt its operation.

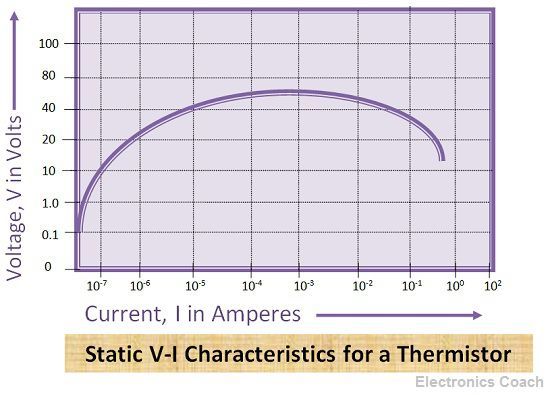

V-I Characteristics of Thermistor

The small current flowing through the thermistor does not cause a sudden rise in voltage, but when the current is increased beyond a particular value, the voltage starts rising. A point is reached after which the voltage starts falling.

The reason behind this is the heating effect increases the current up to a particular value, and thus the voltage drop starts decreasing. It can be understood more clearly with the help of the diagram above.

Applications of Thermistor

- In temperature detector Circuits

- In electrical and electronic circuits, a thermistor is used as a current limiter to protect the circuit from getting damaged.

Applications of PTC thermistor

- As Current Limiters in circuits

- Temperature sensors

- Level Indicators.

- Compensation resistors

Positive temperature Coefficient thermistor (PTC thermistor)

The positive temperature coefficient thermistor possesses high positive temperature coefficient. The absolute value of positive temperature coefficient is much higher than the absolute value of negative temperature coefficient.

The temperature coefficient of PTC thermistor is positive only up to a certain range beyond that range the temperature coefficient is either zero or negative. The PTC thermistors are manufactured by BaTiO3 or SrTiO3. The samples are fired in the oxygen rich atmosphere in order to get high positive temperature coefficient.

If the operating temperature becomes too high, the PTC loses its properties and starts behaving as NTC thermistors i.e. negative temperature coefficient resistor. Thus, it is the limitation of PTC Thermistors that it is suitable for proper working only until a particular temperature.

Leave a Reply